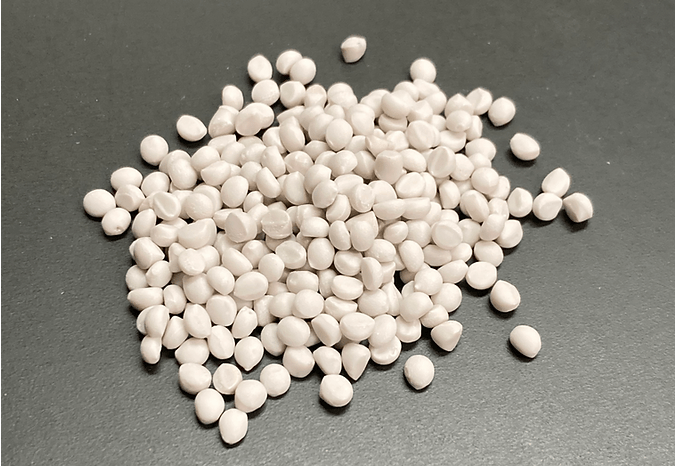

J-STORIES ー Petroleum-derived plastics are a leading cause of CO2 emissions and ocean pollution. A Japanese company, however, believes in the potential of biomass plastics (an organic material derived from living things) as a replacement. And in the process, it has ended years of losses.

Biomass plastic does not add to CO2 emissions when burned, has a low environmental impact, and is a sustainable material that reuses flora and fauna. Yet, it is still not widely produced or used. One obstacle is its price, which is one-and-a-half to five times that of petroleum-based plastics, according to the Nikkei.

Despite such difficult market conditions, Biopoly Joetsu, a specialist manufacturer of biomass plastics based in the city of Joetsu, Niigata prefecture, successfully overcame four years of significant losses to return to profitability.

President Toyoki Takeda told J-Stories why the company continued to work on biomass plastics, even as other companies in the industry went bankrupt one after another. His strong belief is that, “creating new resources from unwanted and unused resources is a smart way for humanity to produce wealth.”

He also told local Niigata media, “I felt that this technology must not be destroyed. I thought our company would definitely be needed.”

The company manufactures bento lunch boxes and chopsticks from unwanted scallop shells, while also producing 200 tons of biomass plastic garbage bags a year from out-of-date rice. About 500,000 tons of scallops land in Japan a year, but about 200,000 tons of shells end up as garbage.

From April 2022 in Japan, a new plastic resource recycling law will come into effect, helping to reduce plastic waste. Biopoly Joetsu is keen to expand the production of biomass plastic products, including developing more types of recycled resources that can be used effectively.

Translation and Editing by Tony McNicol

Top page photo by picturepartners/Envato

For inquires about this article, please contact us at jstories@pacificbridge.jp

***

***

Click here for the Japanese version of the article.

![[Podcast] Japanese technology to supercharge human fertility (Part 4)](https://storage.googleapis.com/jstories-cms.appspot.com/images/1768443226894unnamed-5_bigthumbnail.jpg)

![[Interview] When digital and physical worlds meet](https://storage.googleapis.com/jstories-cms.appspot.com/images/1747974430456unnamed-2_smallthumbnail.png)

![[Interview] How Japanese musician Grover turned his passion of ‘sound’ into a health-tech startup](https://storage.googleapis.com/jstories-cms.appspot.com/images/1746181078493R7__1407_smallthumbnail.jpg)